|

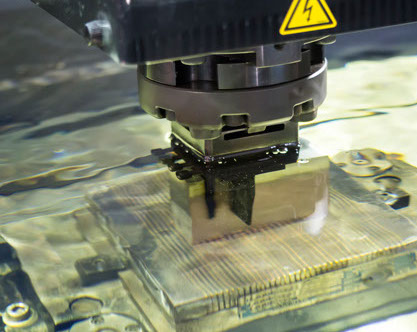

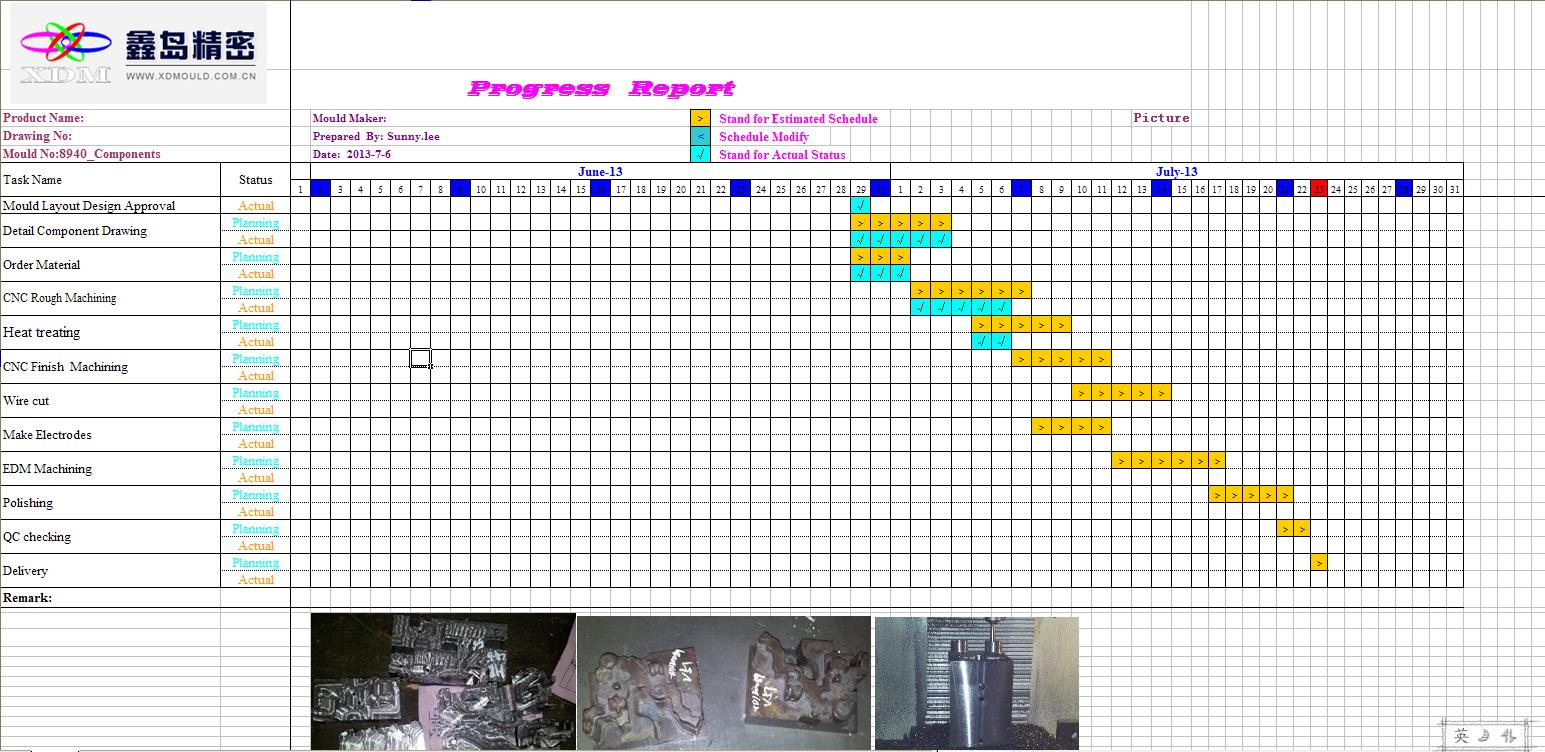

PARTS & COMPONENTS MACHINING —— TIME, QUALITY, PRICE XD MOULD was founded as a machining shop originally and its primary business was parts & components machining in the start-up stage for customers overseas. PARTS & COMPONENTS MACHINING is where the company began and have been growing. As a professional manufacturer of injection mould and parts for over 11 years, XD MOULD has been fully capable of providing highly- quality parts and components for plastic moulds and die-casting tools, with our experienced teams, advanced facilities and outstanding quality control system. We appreciate the opportunity to work for you and your growing business with our expertise and skills. We are here for you with following machining services: 1.Core & Cavity insert 2.Custom Slide & Lifter 3.Spare and replacement parts 4.Other custom parts and components Our standard process:

|

FAQs

Excellent Reputation And Highly Customer Recognition.

- One-stop solution with best price

- Thanks to our skilled, talented and engaged employees ,and having fully equipped advanced facilities, we are able to offer one stop solutions: parts & components machining, design and engineering, mould making, mould trial, plastic moulding, packing and shipping. Every steps of your project is under one roof, ensuring better control of quality, schedule and cost.

- Focus on quality

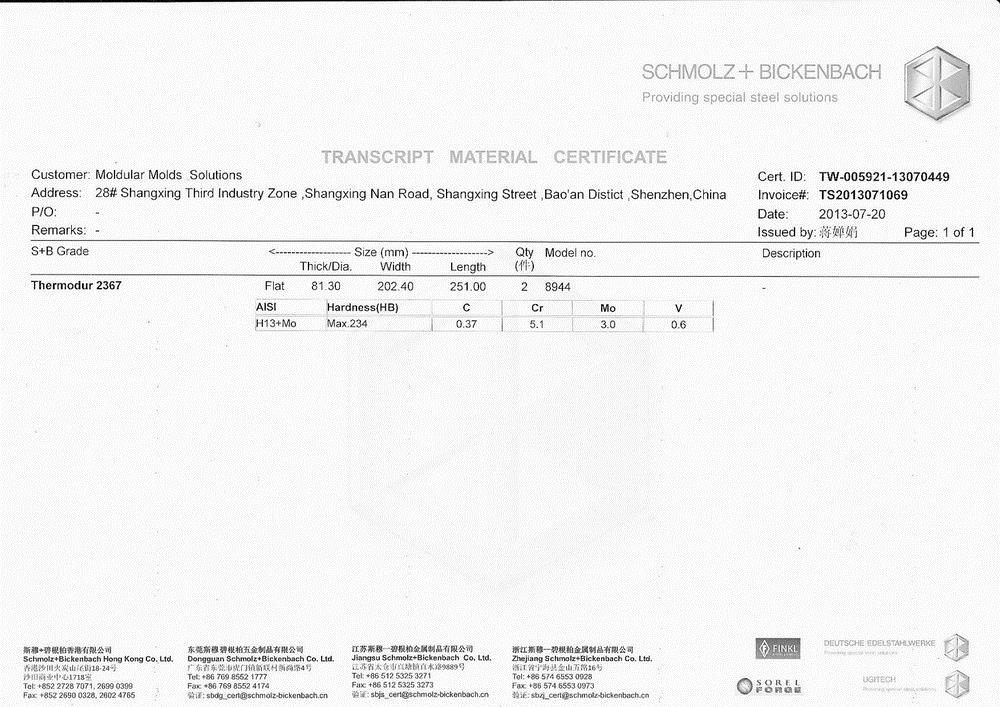

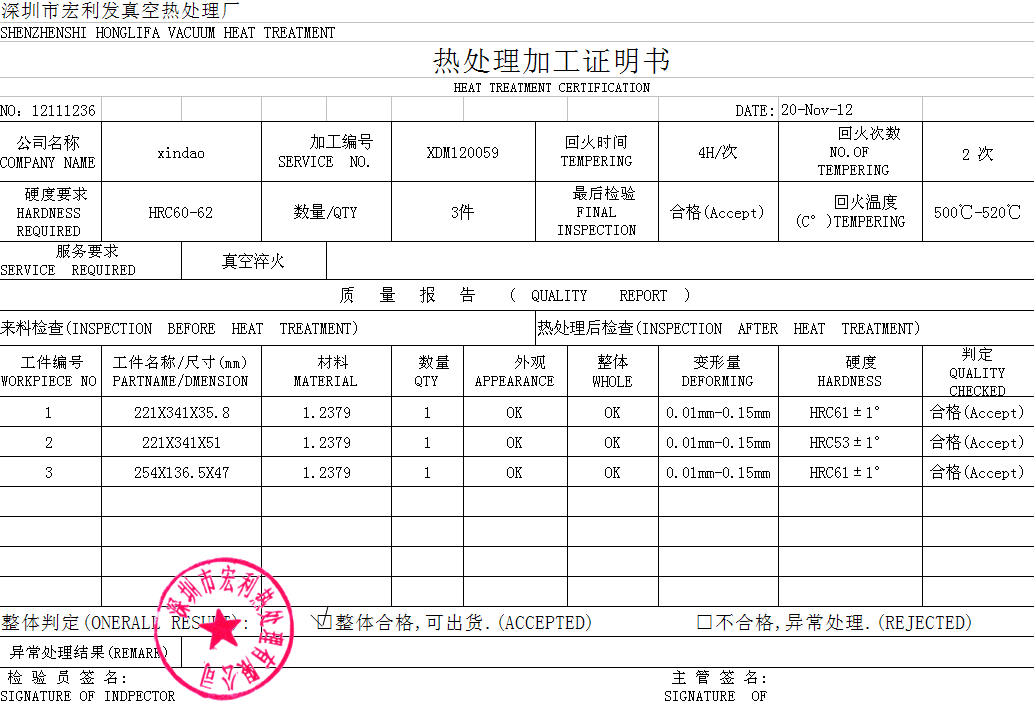

- Quality is a mindset. At XD MOULD, quality is everyone’s responsibility and we never have to stop getting better. Our people are our most valuable resource. We don’t just hire good technicians,we hire good people we can count on. And those good people need good tools to create the quality products. At XD MOULD, we continually invest in the latest technology & equipment, and constantly improve our quality management system to pursue better quality.

HOME

HOME

PRODUCTS

PRODUCTS

SERVICES

SERVICES

CONTACTS

CONTACTS